If you’re looking for a high-performance fiber for your next project, you’ve probably come across Kevlar and Vectran as potential options. But which one is the best choice for your needs vs the many other performance fibers? Both materials have unique properties that make them ideal for various applications. However, there are important distinctions to consider before deciding which material would work best for you.

This blog post will compare Vectran vs Kevlar in terms of their properties, costs, and applications. By the end of this article, you should have a clear idea of which one is the better choice for your specific needs.

Vectran

Vectran is a high-tech fiber formed from a VECTRA liquid crystal polymer (LCP). The global chemical manufacturer, Celanese Corporation, created the material. It’s also manufactured by the Japanese chemical company Kuraray.

Vectran Attributes:

- High tensile strength and rigidity

- Five times stronger than steel

- Ten times stronger than aluminum

- Abrasion-resistant

- Cut-resistant

- High tenacity and modulus

- Excellent elasticity

- Superior impact resistance (bulletproof)

- Dimensional stability

- Vulnerable to UV

- Thermal stability

- Melting point of 330 °C

Structure and Properties of Vectran

Vectran, an aromatic polyester, is created through the polycondensation of 4-hydroxybenzoic acid and 6-hydroxynaphthalene-2-carboxylic acid. The high-performance fiber has a unique chemical structure that gives it an outstanding combination of properties.

Vectran is strong, flexible, and has a low density. The fiber’s special structure also gives it good dimensional stability and low moisture absorption. Often, a polyurethane coating/dye is used around a Vectran core to improve UV resistance.

Applications of Vectran

Vectran is often used in a variety of high-strength applications, such as:

- Reinforcement cords

- Electrical cable

- Sailcloth

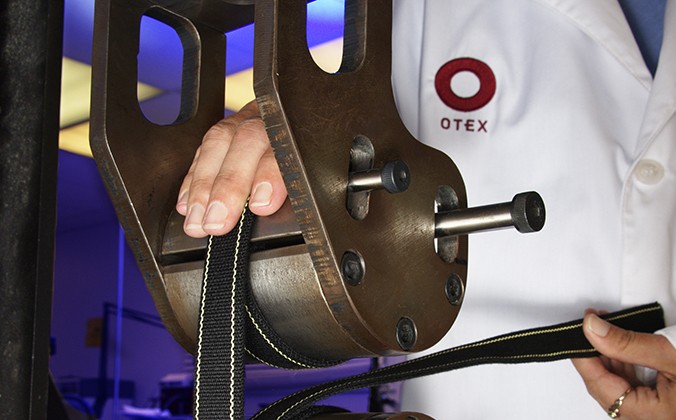

- Webbing and straps

- Parachutes

- Ballistic protection

- Automotive brake lines

- Aerospace

Kevlar

Kevlar is an aromatic polyamide created by DuPont in 1965. It’s a synthetic fiber that’s five times stronger than steel on an equal-weight basis. It’s also known by its generic name, poly-paraphenylene terephthalamide (PPTA).

Kevlar Attributes:

- High tensile strength

- Five times stronger than steel wire

- Twice as strong as nylon fiber

- Cut-resistant

- Abrasion-resistant

- High tenacity and modulus

- Excellent impact resistance (bulletproof)

- Dimensional stability

- Vulnerable to UV

- Superb thermal stability

- Melting point of 450 °C

Structure and Properties of Kevlar

Kevlar is commonly known as a para-aramid material. This is because it has a poly para-phenylene-terephthalamide composition.

Kevlar is a cyclic compound, like aramid fibers, and possesses superb strength. This is because the aromatic rings in Kevlar’s structure are extremely stiff. They’re also tightly packed together, which makes it difficult to slide the molecules past each other. The aramid ring also contributes to the thermal stability of Kevlar, and the para structure accounts for its high strength and modulus.

Applications of Kevlar

Kevlar is used in a variety of high-strength applications, such as:

- Body armor

- Bulletproof vests

- Helmets

- Reinforcement cords

- Webbing and straps

- Car breaks

- Fire-safety PPE

Vectran Vs. Kevlar

Now that we’ve looked at the individual properties of Vectran and Kevlar let’s compare the two materials side-by-side.

Vectran vs. Kevlar: Mechanical Properties

- Vectran: Tensile Strength (grams/per-denier): 23

- Kevlar: Tensile Strength (grams/per-denier): 23

- Vectran: Tensile Modulus (grams/per-denier): 525

- Kevlar: Tensile Modulus (grams/per-denier): 565

- Vectran: Elongation at Break (%): 3.30

- Kevlar: Elongation at Break (%): 3.60

- Vectran: Moisture Regain (%): <0.1

- Kevlar: Moisture Regain (%): 7.0 max

Vectran vs. Kevlar: Performance Breakdown

Both Vectran and Kevlar similar in many areas. But each fiber has its own advantages and disadvantages:

Tensile Strength and Elongation

For reinforcement materials, both fibers have their strengths. Kevlar has been the popular choice as a reinforcement material since the late 60s. Vectran, on the other hand, became available in the late 90s. When comparing the two, tensile strength and elongation are similar, meaning both fibers would suffice for cable and rope.

Thermal Stability

Vectran is hydrophobic (non-porous) and has superior cut resistance, but a lower melting point than Kevlar. Aramid fibers like Kevlar offer increased heat resistance over Vectran fibers. Kevlar is inherently flame-resistant and doesn’t ignite, melt or degrade in heat. Both fibers could be considered ideal for aerospace, automotive applications, and belting cords. But, if you’re looking to maximize thermal stability, choose Kevlar.

UV Resistance

Kevlar has inherently poor resistance to ultraviolet light. The photodegradation effects of UV on Kevlar fibers can cause serious problems like brittleness and surface cracks. Additionally, studies show that Vectran suffers significant drops in tensile strength after UV exposure.

To conclude, neither fiber is superior for daylight outdoor applications where UV exposure is a concern. But, adding a UV-resistant coating to either fiber can improve stability if you’re considering using these fibers in UV-dense settings.

Chemical Resistance

Kevlar has better resistance to most common chemicals than Vectran. However, there are some notable exceptions.

For example, Kevlar is not resistant to strong acids like hydrofluoric acid, sulfuric acid, alkalis, and strong oxidizing agents.

Vectran has better resistance to most acids and alkalis. The only notable exception is hydrofluoric acid, which can cause degradation of the fiber.

The Verdict

So, Vectran vs Kevlar, which is best for you? Both fibers have their pros and cons, so it’s important to do sound research before choosing the right fiber for your specific needs.

The above is merely a summary of the performance abilities and limitations of these fibers. The best solution – when trying to decide the best materials and design for your specialty textile component, is to speak with the experts.

Contact us today. At OTEX, we provide a great variety of performance narrow fabrics using numerous fibers and designs for all different needs. The more we know about your particular needs and goals, the better suited we will be to recommend the optimal product solution.