At OTEX Specialty Narrow Fabrics®, we source advanced fibers from leading manufacturers in the US and around the world. Our Quality Control Department and Test Lab monitor all raw materials from origin through manufacturing and shipment of the final product. Below is a reference table detailing the attributes and applications of some of the commonly used fibers in our high performance and custom products.

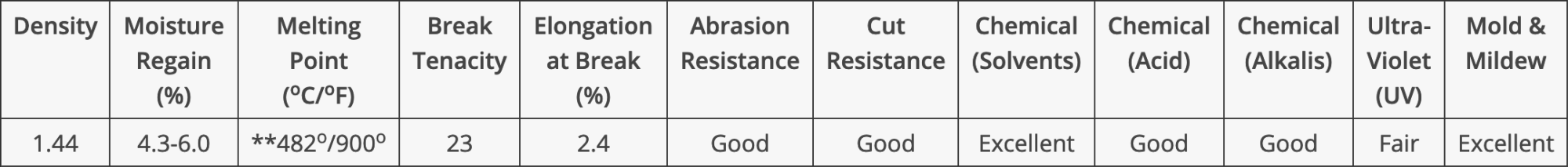

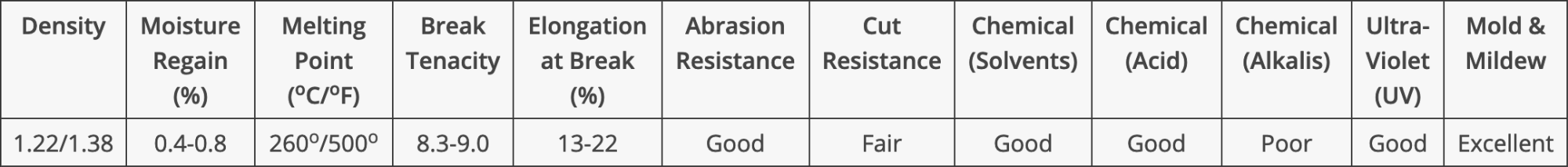

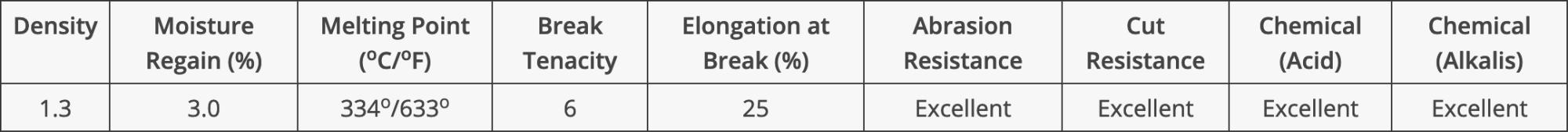

A manufactured fiber in which the fiber forming substance is a long-chain synthetic polyamide in which 85% of the amide linkages are attached directly to two aromatic rings.

Aramid fibers are best characterized by their excellent thermal and strength properties. Aramid fibers do not ignite, melt or drip, making them excellent choices for flame resistant applications. Para-aramids exhibit high heat resistance comparable to that of meta-aramids. The primary distinction between each variation is the superior strength and modulus of para-aramids. Various brands of aramids include: Kevlar®(para), Nomex®(meta), Twaron®(para) and Technora®(para).

Critical component in protective flame-resistant clothing, harnesses and helmets required for aerospace, military, first responders, and industrial safety equipment. The hazards addressed by personal protective equipment (PPE) include physical, electrical, heat, arc-flash, chemicals, biohazards and airborne particulate matter.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

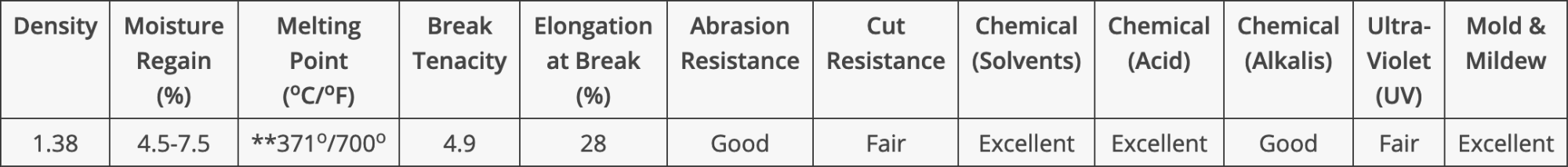

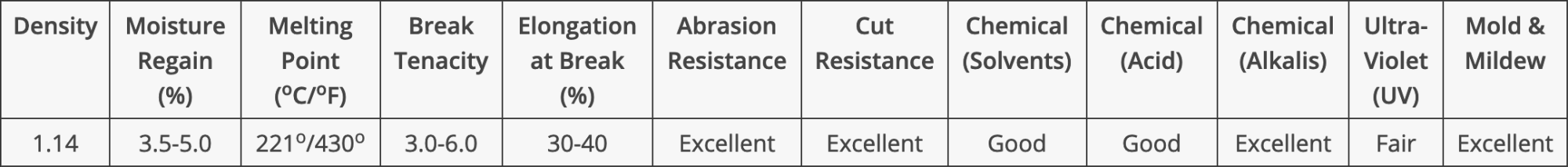

A manufactured fiber in which, when not qualified as a rubber or anidex, the fiber-forming substance is any long-chain synthetic polymer composed of less than 85%, but at least 35% by weight of acrylonitrile units.

Modacrylic fibers exhibit higher levels of resistance to chemicals and combustion when compared to acrylic fibers. They possess arc flash protection properties and are easily dyed with good shape retention. Modacrylic fibers are primarily used where environment or flame resistance is necessary.

Personal protective apparel for fire & arc flash situations, shirt and pant trims, interior and exterior bindings, furnishing and drapery trims.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

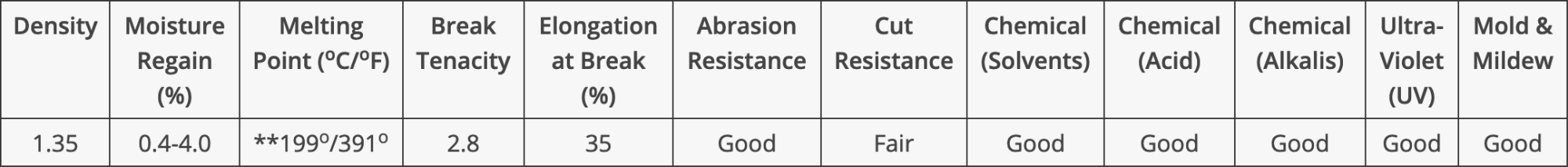

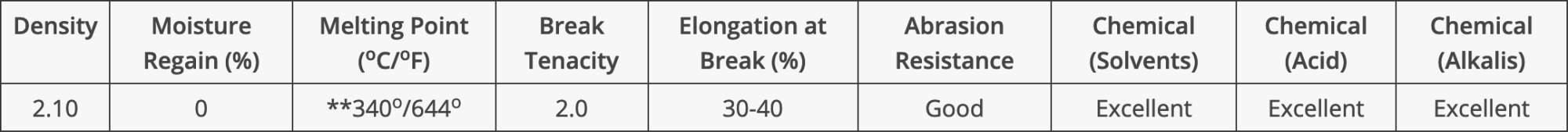

A manufactured fiber in which the fiber-forming substance is a long chain aromatic polymer having recurring imidazole groups as an integral part of the polymer chain.

PBI® fiber exhibits high performance characteristics in a number of areas. It has strong chemical resistance, does not melt, or drip when exposed to flame, and retains its strength and stability – even when exposed to extreme heat conditions. PBI® is generally blended with other high-performance fibers (Kevlar® & Nomex®) to increase tenacity, as well as abrasion and cut resistance.

Common applications

High-performance protective apparel components in firefighter gear and astronaut space suits, arc flash apparel, high-temperature protective gloves, aircraft wall fabrics, can be woven with FR Neoprene for elastic straps and head harnesses/trims.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

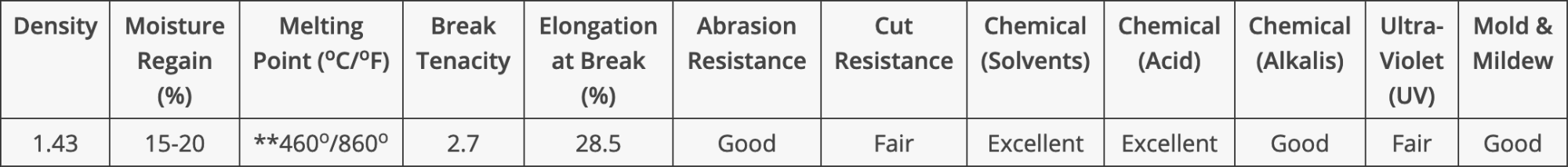

A manufactured fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 85% by weight of an ester of a substituted aromatic carboxylic acid, including, but not limited to, substituted terephthalate units and para-substituted hydroxybenzoate units.

Polyester is a highly versatile fiber that is used across a wide range of industrial textile applications. Polyester fibers have fair abrasion resistance, good electrical insulation properties, and good wearability. It performs well when exposed to elevated temperatures. The most widely used polymer in the production of Polyester fiber is PET (polyethylene terephthalate). Other types include high-tenacity (HT) polyester, PBT (polybutylene terephthalate) fiber which has some stretch capabilities and PEN (polyethylene naphthalate) fiber which is distinguished by its high heat stability.

Industrial ropes, harnesses, straps, conveyer belts and filters, military tents and belts, transportation loading systems, seat covers and straps.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

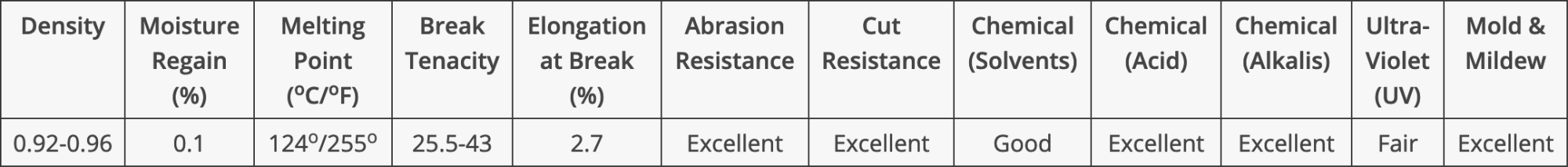

A manufactured fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 85% by weight of ethylene, propylene or other olefin units.

A manufactured fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 85% by weight of ethyleOlefin fibers exhibit extremely high tensile strength, excellent cut/ abrasion, UV, electrical, and chemical resistance. Additionally, they are moisture/water resistant (which helps inhibit mold and mildew), and, in certain cases, they can have elastic properties as well. As a result of their lower density, Olefin fibers have an excellent weight advantage. These fibers are slow burning; however, they do undergo significant shrinkage at temperatures above 60°C/140°F. Olefin (polyethylene/polypropylene) fibers come in multiple densities and fiber types. Spectra® and Dyneema®, both ultra-high molecular weight polyethylene fibers (UHMWPE), are two commonly used brands.

Industrial Safety (fall protection), reinforcements for military vehicles, lightweight military equipment, armor and PPE (personal protective equipment), water towing and rescue systems.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

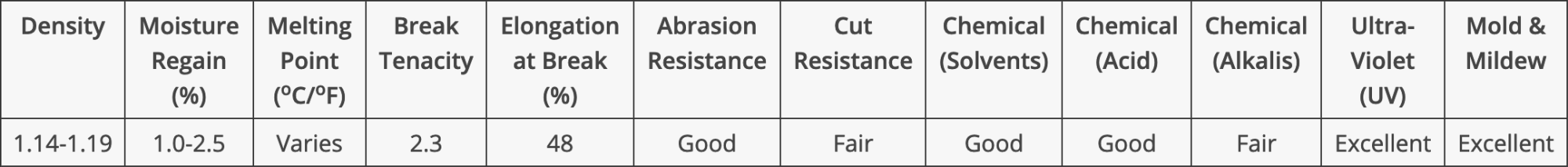

A manufactured fiber in which the fiber-forming substance is any long-chain synthetic polymer composed of at least 85% by weight of acrylonitrile units.

Acrylic fibers have a soft hand, strong resiliency and strength properties, as well excellent resistance to UV, fading and degrading effects of sunlight and mold and mildew.

Outdoor furniture, tents, awnings, architectural structures, marine trims on boat cushions, bimini top covers.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

A manufactured fiber composed of metal, plastic coated metal, metal coated plastic or a cord completely covered by metal.

Metalized fibers can be manufactured in a number of different forms with a wide range of performance properties and capabilities. These fibers are a key element in the development of smart fabrics, wearable e-textiles, conductive webbing for data transfer and physiological monitoring, as well anti-microbial fabrics that inhibit the growth of bacteria and fungi. For more information related to these types of fibers and product customization, please contact OTEX Specialty Narrow Fabrics.

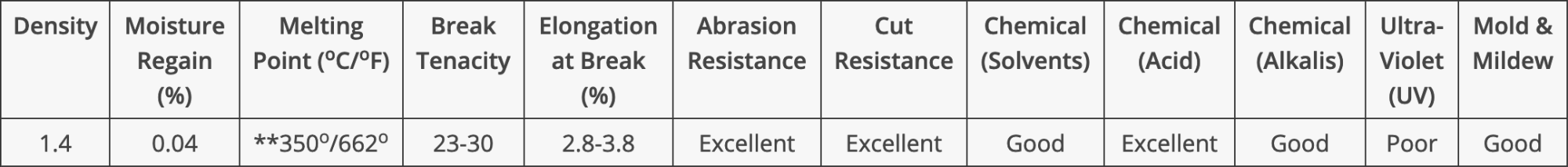

Aromatic polyester fiber spun from liquid crystal polymer (LCP).

Vectran® is a high-performance fiber that exhibits exceptional strength and modulus, high resistance to cuts/abrasion, impact, creep, and moisture, as well as strong chemical resistance properties. Vectran® has excellent thermal stability and retains its properties when exposed to both high and low temperature. The superior strength of Vectran® provides superior load handling characteristics for applications in aerospace, military, ocean exploration, electronic support structures and critical safety and industrial environments. Vectran fibers – in their untreated state – may lose certain performance traits with prolonged UV exposure; however, this can be countered with UV inhibiting dyes and finishes.

Bridle cables, ropes and tethers for inflatable space stations, aircraft slings, cargo strapping for aerospace applications, winch systems, cables and ropes for high pressure inflatables used in environmental disasters, soft goods structures for astronaut mobility units, and arc-flash PPE.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

A manufactured fiber spun from polyetheretherketone polymer.

PEEK is a high-performance fiber with high temperature and chemical resistance. It is commonly used in composites as a matrix material and in other industrial applications.

Fabricated items used in aerospace, automotive and chemical industries, cable insulation, conveyer belts, wire harnesses.

Source(s):

Wellington Sears Handbook of Industrial Textiles

Dictionary of Fiber & Textile Technology

Note:

A manufactured fiber in which the fiber-forming substance is a long-chain synthetic polyamide in which less than 85% of the amide linkages are attached directly to two aromatic rings.

A Nylon fiber, much like polyester, is a very versatile fiber. It is characterized by its good abrasion resistance and is often blended with other fibers to enhance strength and flexibility of the end product. Nylon has good resistance to most strong bases, dilute acids and solvents, as well as low moisture regain and is quick drying.

Industrial webbing harnesses, strapping, ropes, loading systems, slings, rope/cargo nets and automotive and racing safety belts.

Source(s): Wellington Sears Handbook of Industrial Textiles Dictionary of Fiber & Textile Technology

Note:

A fluorine-containing manufactured fiber characterized by its high chemical stability, relative inertness and high melting point.

PTFE fiber has moderate tensile strength, is resistant to the effect of high temperatures and corrosive chemicals and has good electrical insulating capacity. Due to its very low frictional coefficients, it has a slippery hand. PTFE is best known as Teflon®.

Filtration components, protective apparel, electrical insulation, space suits, binding and straps.

Source(s):

Wellington Sears Handbook of Industrial Textiles

Dictionary of Fiber & Textile Technology

Note:

Flame-resistant fibers are materials that have flame resistance as part of their chemical structures. Aramid fibers are inherently flame-resistant fibers. The actual structure of the fiber itself is not flammable. For inherently flame-resistant fibers, the protection is built into the fiber itself and can never be worn away or washed out. In the case of Nomex®, when exposed to flame, the aramid fiber swells and becomes thicker, forming a protective barrier between the heat source and the skin. This protective barrier stays supple until it cools, giving the wearer vital extra seconds of protection to escape.

Flame-retardant treated fabrics are made flame-resistant by the application of flame-retardant chemicals. A chemical additive in the fiber or treatment on the fabric is used to provide some level of flame retardancy. During a fire, chemically dependent fabrics rely on a chemical reaction to extinguish the flame.

When assessing the use of one of the other, keep in mind that flame-resistant fibers have inherent flame-resistant properties that cannot be washed out or damaged through exposure to chemicals in the workplace or laundering. Flame-retardant treated garments, however, may be damaged by chlorine bleach, the combination of hydrogen peroxide (“oxygen bleach”) with hard water, or exposure to oxidizing chemicals in the workplace.