By: Bruce N. Wright

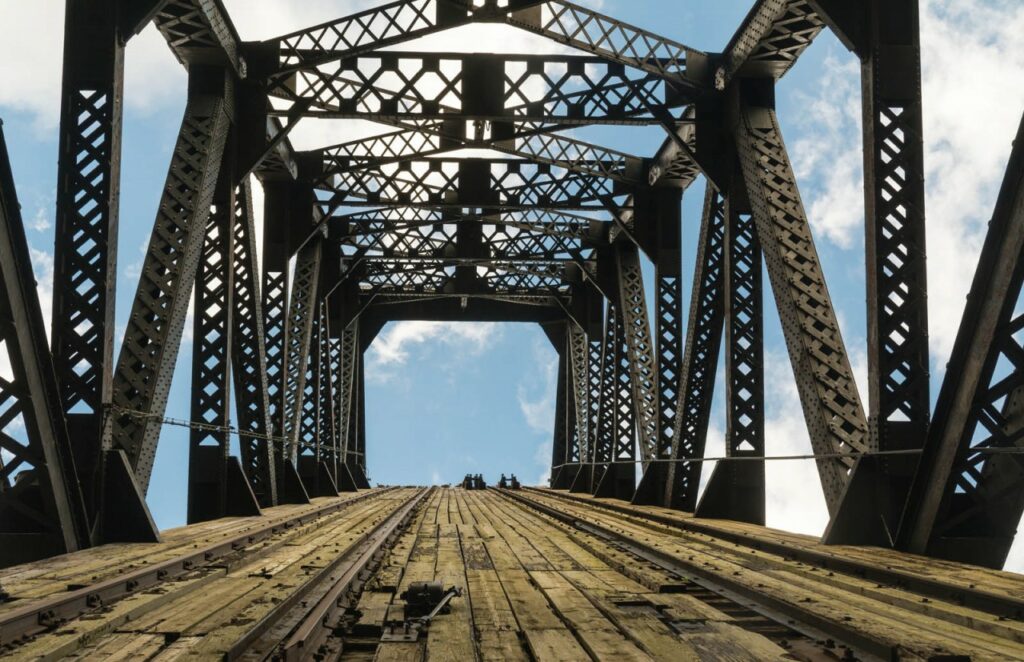

During the evening rush-hour traffic, the eight-lane 35W bridge over the Mississippi River in downtown Minneapolis suddenly collapsed on August 1, 2007, killing 13 people and injuring 145. The bridge was a continuous truss design, and an overstressed gusset plate at a critical joint was later determined as the weak point that contributed to its demise. Since then, some in the interactive textiles industry have speculated that if the technology of sensor fibers and reactive materials had been sufficiently advanced at that time, data produced by these smart textiles might have helped prevent the bridge’s collapse by alerting officials to critical conditions before it was too late.

Massive infrastructure revitalization—not only of bridges, but also railways, tunnels, and oil, gas and water pipelines—is needed across the country, and many experts agree that this process will be difficult and expensive. Researchers at the University of Massachusetts Lowell (UMass Lowell) recently announced that their research and development of sensing textiles can be used to speed up the revitalization process and reduce the cost of assessing the structural health and integrity of infrastructures across the country.

Initially focused on pipelines and tunnels, the UMass Lowell researchers have developed integrated fabrics with optical fibers and sensors designed to monitor strain or detect cracks at an early stage in the life of existing structures, including buildings.

“The process of monitoring below-ground infrastructure, up to now, is time-consuming and dangerous,” says Dr. Tzuyang Yu, associate professor at UMass Lowell and team leader in the R&D of these sensing fabrics. “This can have significant social cost and disruption. The older method may have tens of discrete sensors placed on the surface of a pipeline or tunnel to monitor its integrity.” In contrast, the UMass Lowell’s system will have hundreds of data points, providing a measure of at least two orders of magnitude higher, says Yu, giving more accurate and timely data analysis. “This research project combines what I like to call a ‘marriage’ of two very old fields: civil engineering and textiles.”

The university is collaborating on this research with experts from Saint-Gobain ADFORS America, and the system involves optical fibers that are converted into wide area sensing textiles using SaintGobain’s proprietary fabric-forming technology. The team expects the system to be available soon to monitor aging infrastructure in countries around the world.

Human monitoring opportunities

Interactive textiles have the ability to accomplish much that cannot be done with other technologies. “There are tremendous possibilities for smart textiles,” says Dr. Qaizar Hassonjee, president of Hass Tech Associates, Philadelphia, Pa., “in part because many people in businesses related to crisis management and safety can personally understand the importance of smart textiles as a part of their existence. This is particularly true for first responders in a situation where people are not able to judge the true conditions of a disaster without complete data. A smart textile that is part of an integrated system of information collecting can help them better understand what’s needed to respond to a crisis.”

“We are already seeing fire and hazmat suits get fitted with sensing monitors that check the physiology of first responders,” says Hugo Trux, executive director, Conductive Fiber Manufacturers Council. The next level of integration, Trux believes, will dial down to the level of clothing fabric. “These systems are totally integrated, linking signals between the responders and command; the clothes and the technology are now one and the same. The suit itself is able to communicate automatically from each person wearing the technology.

“A fiber could carry a signal that measures the oxygen intake of a person with one of these integrated suits, [who] can be checked by a supervisor at the site on a screen that shows the entire building under alert,” continues Trux. In this scenario, the supervisor can see where all the responders are located throughout the building and then quickly evacuate the person in need.

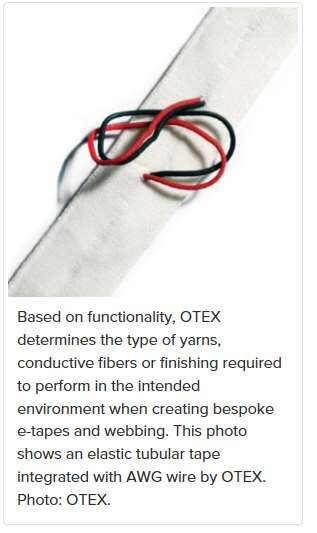

One company intimately involved with this market is OTEX Specialty Narrow Fabrics® Inc., Bernardsville, N.J., which engineers and manufacturers high-performance narrow fabric textiles that are used in numerous critical situations. OTEX collaborates with diverse industry clients on customization, consultation, prototyping and full production of electronically integrated textiles, or “etextiles.”

“We have the ability to integrate wire and conductive thread configurations into a woven textile that becomes the linking fabric used by our clients to assemble additional electronic or media components such as connectors, sensors, circuit boards, apps and a power source,” says Timothy E. Offray, executive vice president of business operations for OTEX. “Our e-textiles have been used in an assembly that connects the user to a smartphone app, analyzing body form, performance stats and acting as a digital coach.”

OTEX is engaged in multiple ongoing R&D projects with clients to engineer e-textiles that enable power, voice, or data transfer or that harvest energy. Offray agrees that a primary opportunity for interactive materials and textiles is the first responder market, but also sees other areas that could benefit from the technology, including industrial safety, military and medical markets. However, Offray says this expansion will not be simple, particularly because of the multiplicity of players and lack of common guidelines. “There is a spectrum of challenges allied to supply chain management and working without industry guidelines for the finished product,” says Offray.

“The e-textile supply chain combines several different industries and disciplines, each with their own language, lead times, standards, regulations and expectations. These include manufacturers of yarn, wire/cable, weaving, textile compatible connectors, hardware, sensors; end-product design, engineering and assembly; and a testing regime for multiple individual components and the complete assembly.”

Auxetic textile developments

In addition to the e-textile sensing approach, there are a number of other up-and-coming technologies that are embracing the challenges and opportunities of crisis management and safety product development: textile composites (seismic performance monitoring), auxetic (protective or containment), piezoelectric (power generation), and phase change materials (thermal control). Perhaps the fastest to the market of these technologies are those that utilize auxetics or auxetics in combination with signal or energy transmission technologies.

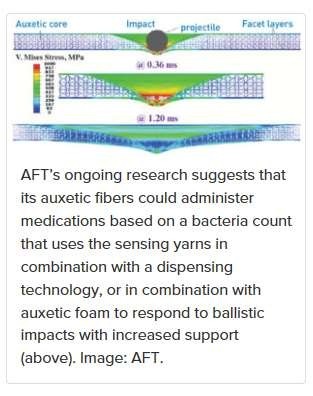

Advanced Fabric Technologies Inc. (AFT), Spring, Texas, has developed an auxetic fabric that is directed to the blast-containment markets. Its Xtegra™ yarn is composed of an elastomeric core fiber and a wrapped fiber of a smaller diameter. The wrapping creates an auxetic effect that, as the yarn is pulled, causes an effective increase in diameter of the assembly, making it thicker and stronger. It’s already being applied to blast protection for military IED (improvised explosive device) containment, fire proofing and offshore oil rig situations. Recent developments have encouraged AFT to explore new markets.

“The initial auxetic patent was focused on mitigating the effects of explosions,” says David O’Keefe, CEO and president of AFT. “However, through several years of R&D, AFT discovered that auxetic geometry could enhance the use of traditional solutions in wound care. This technology can treat many problems associated with diabetics and for people with bad circulation in their extremities. We currently are working on several concepts that are not just ideas, but are in actual modeling stages. Because of our experience in the blast/fragmentation arena, we’ve created an auxetic baseline that can be used to develop solutions by incorporating auxetic yarns for use in any number of textile applications.

“The great thing about auxetics is it is not limited to certain fiber groups,” says O’Keefe. “It depends more on the application. As a smaller company, we cannot do this alone; hence we’ve partnered with other companies. Auxetic geometry is a wonderful technology, but it has not been commercially exploited to any great extent. However, it is a disruptive technology and initially difficult to understand or accept readily by traditional thinking. A great deal of education will be needed toward the acceptance of auxetic technology, including the willingness to redesign some aspects of manufacturing.”

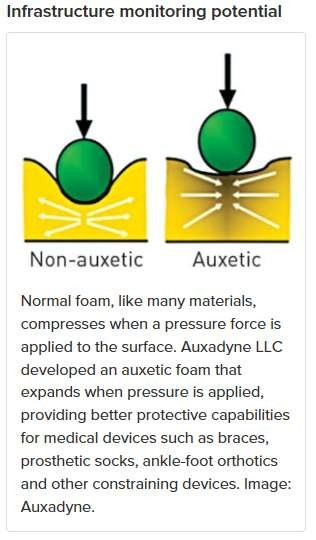

Auxadyne LLC, Keystone Heights, Fla., makes auxetic foam for protective equipment for sports, military and first responder applications, as well as for orthotic and prosthetic medical devices. It is also developing a pre-production piezoresistive technology that works with the foam as a substrate and promises to produce improved sensitivity (“up to 400 percent greater”) over conventional foams.

“The auxetic nature of our foam enables instantaneous and autonomous volumetric changes in response to inflammation and recession cycles,” says Joe Condon, president/CEO of Auxadyne. “This results in constant clinically desirable pressure, important in certain medical devices including braces, prosthetic socks, ankle foot orthotics and other constraining-type devices.”

However, pushing the new technology into the world market is no easy matter, says Condon. “The current primary challenge is marketplace resistance to displacing current ‘adequate’ foam pad solutions and a lack of understanding of the clinical benefits and advantages of our new technology.”

Future markets: not so fast!

Challenges in converting new technologies to production rate commercialization have always been with us. Steam locomotives and automobiles were viewed as novelties when they first appeared, so it is not surprising that new technologies like interactive textiles will need some time to become commonplace.

However, technical challenges will need to be solved first. “With conductive fibers,” says Trux, about future integration of e-textiles, “the separation between a wire carrying the signal and the clothing must be eliminated. Before, to integrate a sensing device into a suit, the wire had to be carefully inserted into the suit with a protective separation like a membrane, or it could sometimes be woven into the suit. Now, with conductive fibers this function can be embedded into the fabric itself.”

What can innovators expect in the next five to 10 years for interactive textiles? Certainly, steady adoption and increasing to-market production, but there should be careful consideration of which technologies could be used for what applications. Hassonjee recently spoke in Washington, D.C., at IFAI’s Smart Fabrics Summit, co-hosted with the U.S. Department of Commerce, about the challenge of pushing the market forward. He discussed the challenge of identifying smart textile applications that provide real value in the marketplace.

“The question is, is there value in the tremendous amount of data that we see being collected today? We really need to provide actionable insights,” says Hassonjee. “For this data to be useful, we need to understand it, to dig into it and develop insight before using it. Smart textiles can contribute to this insight, but applying them has not happened at the rate predicted even 10 years ago. The market for smart textiles hasn’t grown as large as predicted because businesses haven’t recognized the right applications or identified the needs. Consumers can’t be expected to drive this growth unless they get real value. It must come from the specific market needs and that means ‘market back innovation’ starting with the end user/consumer and then working back to the insight that needs to be developed and the technology required to create the insight. This is different from the technology-forward innovation that we have pursued for smart textiles in the last 10–15 years. It needs unique experiences that, with the smart textiles, can benefit from the technology in an appropriate use.”

Bruce N. Wright, AIA, consultant to architects and designers, writes frequently about architecture, design and textiles for Specialty Fabrics Review, Fabric Architecture, Advanced Textiles Source and other international journals.